Logging Equipment

Status: Operational, static display

The crawler tractor revolutionised the logging industry. Benjamin Holt produced the first commercially successful track-laying tractor in 1904. This machine was fitted with independent clutches in the drive to each track and produced the manoeuvrability for which this type of tractor was to become renowned. In 1910, Holt registered the name “Caterpillar” for his new tractor, and the fore-runner of the machine which was to revolutionise logging and road making around the world was born. Following the 1914-1918 war, the crawler tractor made steady inroads into the displacement of steam and animal power for logging on the West Coast of the USA. The Holt Tractor Company merged with its major rival the C. L. Best Traction Company in 1925 to form the Caterpillar Tractor Company. This new firm, along with the Cleveland Tractor Company (Cletrac), Allis-Chalmers and McCormick-Deering supplied the majority of tractors used in Australian logging.

The major drawback of the crawler tractor was that the initial investment was relatively large. While a double-drum steam winch and boiler could be purchased for around £1000 in 1936, a new Caterpillar tractor fitted with a blade cost between £1860 and £2590 depending on the model and “gauge” of the tractor. The addition of a PTO winch could add between £225 and £425 to the purchase price. Smaller tractors, such as the Cletrac and the McCormick-Deering “TracTracTor”, could be purchased for around £1200. Even so, the total purchase price of a fully-equipped crawler tractor roughly equalled the cost of equipping a small bush sawmill, so the new technology was only available to sawmill owners who commanded sufficient spare capital to make the purchase. The first crawler tractor was introduced into the forests near Alexandra in 1933-34. By 1937, twelve out of the twenty-three sawmills in the district were employing a crawler tractor.

Status: Operational, under restoration

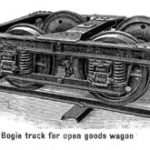

The first steel-framed bogies used on the Rubicon to Alexandra tramway were purchased in 1911 by the Rubicon Lumber & Tramway Company. These trucks were a product of “Bochumer Verein für Bergbau und Gusstahlfabrikation” [Bochum Union for Mining and Steel Casting Manufacture]. The Company’s works were established in the Ruhr industrial district at Bochum, Germany, in 1842, and its products won two first prizes at the Centennial Exhibition in Melbourne in 1888. It employed between about 9,000 men, and had its own collieries and iron ore mines producing 650,000 tons of coal and 40,000 to 60,000 tons of iron ore per year. Bochum Union had its own works railway with forty kilometres of track, twelve locomotives and 350 wagons. Its catalogues offered everything from a single truck to a complete light railway, including locomotives. The Company is still in the railway business today.

When the Lumber Company lost control of the Rubicon tramway in 1935, the Bochum Union trucks were set aside until purchased with the rest of the Company’s assets by Ruoak Timbers in 1938. Seventeen Bochum Union trucks survive today at the ATT.

Status: Static display

Many of the steam logging winches used in Victorian logging were cobbled together from whatever equipment the sawmiller could be purchase cheaply. However, one Victorian manufacturer produced a winch of such quality and in such volumes that it was never surpassed by any other locally-made variety. The Harman winch was manufactured by Alfred Harman & Sons at their Port Melbourne engineering works. The winch, patented in 1913, related to features of the cast-steel upper frame. A second-motion winch, it featured cylindrical trunk guides, flat “D” slide valves, Stephenson’s link reversing gear, a cast steel frame mounted on rolled steel joists and twin cast steel drums. The winch was available as “a pair of eights” or a “pair of tens” depending on the cylinder diameter.

Status: Static display

One very special exhibit at the Alexandra Timber Tramway is the working sawmill model, mill settlement and tool display housed in “Ernie’s Room”. Ernie Le Brun started work in the Rubicon Forest in 1927 and, apart from service in the Second World War, he and his wife Rose were to live and work there almost continuously until 1962. The models Ernie built for the ATT are a major part of his legacy to the heritage of the Rubicon Forest.

Ernie became “bush-boss” for the Rubicon Lumber & Tramway Company, and specialised in rope-work for winches. Where steep terrain was encountered, a useful method of rigging the wire ropes for the winch was to put them up a tall tree. This tended to raise the nose of the log off the ground, clearing obstructions on the ground more easily. This technique was called “high-lead snigging”.

To get the bull and gin-wheels up the tree, a specialist “high-climber” was used. This was one of the many skills mastered by Ernie Le Brun, and his climbing gear is on display today at the ATT. Special spurs were attached to the climber’s feet. These projected on the inside of his legs below his boots and were dug into the tree to obtain a foothold. A wide leather belt and a rope around the tree allowed the climber to keep his balance. This was slow, difficult and dangerous work, especially if the top of the tree had to be cut off to get the rigging high enough.

To complement Ernie’s models and climbing gear, there is a display of timber workers’ tools and a wide range of photographs showing work at the mills and on the tramways. In addition, there is a video presentation outlining the story of Ernie and Rose Le Brun as told in their own words.

Status: Static display

This logging winch was constructed by the Steel Company of Australia of Brunswick. A third-motion winch, it features cylindrical trunk guides, flat “D” slide valves, Stephenson’s link reversing gear, a cast steel frame mounted on rolled steel joists, and twin cast steel drums. Most winches were of the second motion type, and the additional intermediate drive shaft on this winch provided very low gearing and hence additional power.

This particular winch was used by Ruoak Timbers at the far end of its log line supplying the No.5 mill in the Rubicon Forest. It was removed from the bush along with its Ruston Proctor “bottleneck-jackass” boiler when the mill closed in 1952 and, for many years, lay outside J. L. Gould’s sawmill in Alexandra before the machinery was reunited at the Alexandra Timber Tramway in 1988.

This winch site has been set up using advice from former Rubicon Lumber & Tramway Company “bush-boss” Ernie Le Brun, and is maintained as a memorial to the twelve men who died at Rubicon in the bushfires of 1939.

Status: Static display

The wire-rope work associated with the Steel Company winch site illustrates the method used to winch logs in from the bush. The thicker of the two ropes is called the “main rope” and is used to haul the log in towards the winch site, and runs through a series of large pulleys known as “bull-wheels”. The thinner of the two ropes or “straw-line” is used to haul the main rope back out into the bush, and runs though a series of smaller pulleys known as “gin-wheels”. At the far end of the run, a gin-wheel attached to a suitable tree made the whole system a very functional “endless loop”. Both ropes are wound on separate drums on the winch, which revolve in opposite directions.

At the point where the two ropes joined, a “dropper” was installed to attach the log to the haulage system. As the log approached each bull-wheel, the winch would be stopped, the dropper shifted to the winch side of the bull-wheel, and the process repeated. Using this arrangement, a winch could systematically log an area of forest around a radius of more than a kilometre from where the winch was sited.

A number of people were required to carry out this work. Pairs of “Fallers” felled the tree, cut off the top and then cut the trunk into suitable-length logs, the “swamper” cleared the route along which the log would be “snigged” to the winch, the “whistle-stringy” signalled the winch driver as to what was required by pulling on a whistle-wire running alongside the route of the main rope, while the winch driver tended to his winch and fired the boiler. Once at the landing adjacent to the winch, the “timber truckies” would load the log onto pairs of log bogies for transport over the tramway to the mill. Using this system, a good crew could supply about eight logs a day to the sawmill.

This rope-work was installed in 1990 by Ernie Le Brun, former “bush-boss” for the Rubicon Lumber & Tramway Company, and in charge of the Company’s winch operations for many years.